Exact Welding Inspection Service for Steel Construction

Exact Welding Inspection Service for Steel Construction

Blog Article

Unlocking the Secret Sorts Of Welding Solutions for Your Projects

In today's landscape of varied welding solutions, recognizing the subtleties and applications of various welding methods is critical for effective job implementation. From generally utilized methods to sophisticated innovations, the world of welding offers a range of opportunities to satisfy various job requirements. By untangling the essential types of welding services available, one can browse the details of picking one of the most appropriate technique to ensure accuracy, performance, and high quality in welding projects. As we embark on this expedition of welding services, a much deeper insight right into the world of welding waits for, promising understandings that can boost the results of your tasks.

Typical Welding Strategies

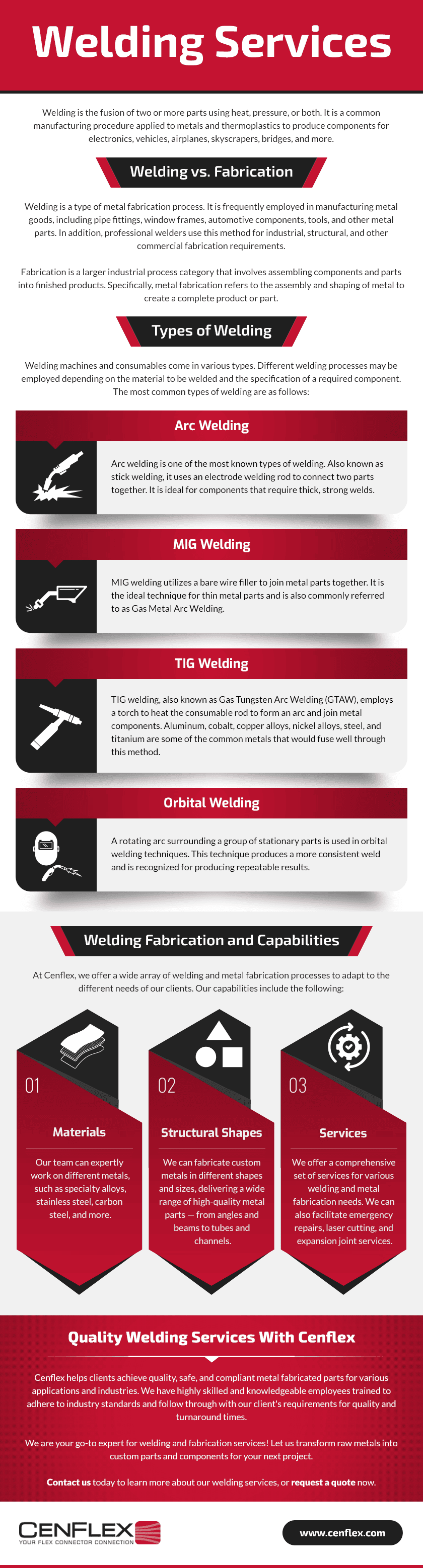

Several typically utilized welding strategies play essential roles in various commercial markets. One of the most extensively used methods is Gas Steel Arc Welding (GMAW), likewise recognized as MIG welding.

An additional preferred welding strategy is Gas Tungsten Arc Welding (GTAW), generally referred to as TIG welding. TIG welding utilizes a non-consumable tungsten electrode to create the weld and calls for a different filler material. This technique is preferred for its control, capability, and precision to produce premium welds on thin materials.

Shielded Metal Arc Welding (SMAW), or stick welding, is an additional crucial method where a flux-coated electrode is made use of to produce the weld. SMAW is recognized for its simplicity, convenience, and viability for on-site and outside welding applications. These common welding techniques are essential for producing frameworks, equipment, and numerous devices throughout sectors.

Advanced Welding Processes

Advanced welding processes incorporate cutting-edge strategies that press the boundaries of standard welding methodologies in terms of precision, performance, and convenience. One such procedure is laser beam welding, which uses a focused beam of light of light to sign up with metals with marginal heat-affected zones, making it ideal for delicate or high-precision jobs. Furthermore, electron light beam welding employs a high-velocity electron beam to develop deep welds in thick products, providing extraordinary toughness and high quality.

In addition, rubbing mix welding is a solid-state joining procedure that makes use of a revolving device to develop frictional warm, bonding products without thawing them. This method is specifically useful for joining lightweight alloys with premium mechanical buildings. One more ingenious method is ultrasonic welding, where high-frequency ultrasonic resonances are utilized to produce solid-state welds in plastics, metals, and various other products, providing fast and tidy joining solutions.

These advanced welding procedures satisfy a varied variety of commercial requirements, supplying efficient, premium, and exact services for various tasks, from aerospace elements to automobile components and past.

Specialized Welding Applications

Automated Welding Solutions

In modern-day industrial setups, the execution of automated welding solutions has actually reinvented production procedures by improving performance and accuracy. Automated welding systems utilize innovative modern technologies such as robotics, computer numerical control (CNC), and expert system to execute welding tasks with very little human treatment (Welding Inspection Service). These systems supply numerous benefits, including boosted efficiency, boosted weld high quality, and reduced manufacturing prices

One secret benefit of automated welding services is their capability to constantly generate top quality welds, causing boosted overall item high quality. In addition, these systems can operate constantly, 24/7, without the requirement for breaks, leading to greater output levels and faster job completion times. By using automated welding options, firms can likewise alleviate the dangers connected with human error, guaranteeing greater precision and repeatability in the welding process.

Additionally, automated welding options are adaptable and very functional to different welding applications, from complex elements to massive structures. Whether in automobile manufacturing, aerospace industries, or construction tasks, the assimilation of automated welding systems uses an affordable edge by enhancing procedures and delivering exceptional welding outcomes.

Innovative Welding Technologies

The advancement of automated welding solutions has actually led the way for the integration and innovation of ingenious welding technologies in contemporary commercial applications. One such innovative innovation is laser beam welding, which uses a very concentrated beam of light of light to join steel components with accuracy and effectiveness. This method is especially useful for projects needing intricate welds on products with high melting points or for applications where very little heat-affected areas are important.

Another ingenious welding technology getting appeal is friction mix welding (FSW), a solid-state joining procedure that develops high-strength bonds by generating frictional warmth between two items of metal. FSW visite site is commonly made learn this here now use of in industries such as aerospace and automobile for its capacity to produce welds with remarkable mechanical residential properties and enhanced structural honesty.

Furthermore, electron beam of light welding (EBW) is an innovative technique that utilizes a beam of light of high-velocity electrons to develop precise, deep welds in metal elements. This modern technology is favored for its ability to weld different steels and materials with varying densities effectively. As markets remain to demand better and effectiveness in welding processes, these innovative modern technologies are positioned to play a considerable role in shaping the future of commercial welding applications.

Verdict

Finally, understanding the essential types of welding services is important for effectively completing a selection of tasks. From usual welding strategies to innovative procedures, specialized applications, automated options, and ingenious innovations, each technique provides distinct benefits and applications. By familiarizing yourself with these various welding options, you can choose one of the most suitable method for your details task demands and attain high-quality results.

In today's landscape of varied welding solutions, comprehending the nuances and applications of numerous welding methods is critical for successful task execution. By unwinding the essential kinds of welding solutions available, one can browse the complexities of picking the most ideal method to make certain accuracy, effectiveness, and quality in welding projects. As we embark on this expedition of welding solutions, a deeper understanding into the globe of welding waits for, encouraging insights that can boost the results of your tasks.

Report this page